Biocompatible polymers commonly used in the orthopedic and cosmetic prosthetics, cardiovascular and dental implants and food packaging industries often suffer from poor mechanical properties and thermal stability, limited dimensionality and short shelf-life as compared to their metal comparators. Two research groups from the Weizmann Institute of science and Tel-Aviv University, have demonstrated the Integration of inorganic tungsten sulfide nanotubes (WS2-NTs) into standard polymer solutions, without impacting viscosity. When deployed in standard fused deposition modeling processes, the reinforced polymers present uniform dispersion of the WS2-NTs, usually hard to achieve using other nanoparticles such as carbon nanotubes or graphene, and preserved crystallinity. Fabricated products are biodegradable and biocompatible, and demonstrate substantially enhanced mechanical strength and fracture toughness as compared to neat polymer solutions. The WS2-NTs-reinforced polymer can serve as ink for 3D printing of a range of products, including custom-designed orthopedic, cardiovascular, dental and plastic surgery implants and prostheses, and may be advantageous in the food packaging industry.

Additive manufacturing (AM), also known as 3D printing, features high material and design versatility and precision. It has evolved to be the central technology for the fabrication of custom-made medical implants and prosthetics, particularly in orthopedics, dentistry, and plastic surgery arenas. Fused deposition modeling (FDM), the most commonly used AM technique, involves layer-by-layer deposition of heated thermoplastic filaments, which rapidly solidify to form the final shape. While thermoplastic polymers provide for rapid, low-cost and relatively simple fabrication of light-weight structures, the final products suffer from mechanical weakness, rendering them inferior to metal alternatives. Moreover, the rising demand for multifunctional materials in a range of medical and food industries has increased the need for polymer optimization. Integration of carbon nanotubes (CNT) or graphene into materials used in AM, has been shown to reinforce polymer matrixes, but is associated with toxicities, impaired material viscosity and difficulty with achieving uniform nanoparticles dispersion.

A novel technology enhancing the mechanical properties of biodegradable polymers by doping polymer solutions with tungsten disulfide (WS2) nanotubes (WS2-NTs), an inorganic, nontoxic material dispersible in both organic solvents and polymers.

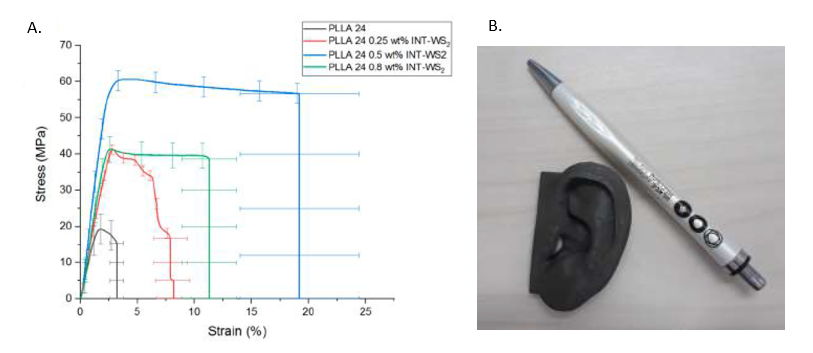

The technology developed by this group generates biodegradable and biocompatible WS2-NTs-reinforced poly(L-lactic acid) (PLLA) nanocomposites and other polymers from this family to be applied in standard 3D printing processes. When used as a feeding filament in an FDM process, melt-extruded, solvent-free WS2-NTs-PLLA nanocomposites showed preserved viscosity and proved simple to use, without requiring solvent-supported dispersion or any printing parameter adjustments. Furthermore, the entire process did not require any modification of the printing process, other than mixing the nanotubes in the polymer matrix. During the printing procedure, the WS2-NTs became evenly dispersed along the nanocomposite filament diameter, and crystallinity was preserved. The resulting reinforced PLA-WS2 composite demonstrated a 20%, 23%, and 35% increase in elastic modulus, yield strength and strain-at-failure, respectively, as compared to neat PLA. The toughness increased by no less than 100% and above. The researchers demonstrated this method's applicability in custom-tailored printing of prosthetic organs for dental, orthopedic, and plastic surgery applications.

A. A stress–strain curves of PLLA films with different weight percentages of INT-WS2 with error bars. The results for each specimen represent an average value of five samples. B. FDM printing with the WS2-NT-PLLA composite. An undyed model of a human ear printed from WS2-NT-reinforced PLLA ink (pen to scale). From: Lubricants 2019, 7(3), 28.

Advantages

- Biodegradable and biocompatible

- Improved mechanical and rheological properties

- Processing flexibility, compatible with 3D printing technologies

- Easily dispersed in the polymer solution without affecting viscosity

- Enhanced thermal stability

- Reduced material friction

Applications

- 3D printing and other advanced polymer applications

- Custom-made biodegradable soft implants

- Biodegradable soft stents

- Bone engineering

- Integration with hydroxyapatite for increased material hardness

- Scaffolds for tissue engineering.

The researchers successfully demonstrated the incorporation of WS2-NTs into PLLA with high dispersion. The addition of WS2-NTs increased the elastic modulus, yield strength, and strain-at-failure. In addition, the researchers found that the printing process itself improved the dispersion of WS2-NTs within the PLA filament (published in: Lubricants 2019, 7(3), 28). The researchers are planning to include hydroxyapatite in the filament to further increase material hardness (initial results published in: Int J Mol Sci. 2018, 19(3): 657), AM experiments will be done by the group from Tel-Aviv University. The nanoparticle polymer reinforcement technology is patent-protected.

With the rapid advancements in 3D printing technologies, customized 3D medical implants and models are witnessing an increasing demand across many medical sectors, the global 3D printing healthcare market for instance is valued at USD 970M and is expected to more than quadruple in size by 2026. In parallel, the $1B worth 3D-printed dental implant market is growing at a CAGR of 18%. One of the largest market increases is expected in the personalized 3D-printed orthopedic implant and prosthesis market, constitutes the majority of the AM-fabricated medical technology market is poised to grow by USD 1.24 billion during 2019-2023, progressing at a CAGR of nearly 26%.

Dr. Vered Pardo Yissar