Inertial sensors for motion detection are being incorporated into an increasing number of portable devices, including diverse IoT applications, mobile phones, wearable electronics, automotive systems and medical diagnostic sensors. The current size reduction trend in electronics, requires incorporation of reliable nanoelectromechanical systems (NEMS) into nanosensors, yet market applications of NEMS are currently limited by high costs of fabrication and inconsistent quality. A new technology developed by a group of researchers from the Weizmann Institute, provides a unique, highly reproducible structure for inertial nanosensors, with high durability at the nanoscale and with a detection mechanism based on the piezoresistive effect. The invention further extends application opportunities of extremely small portable electronics, which, with the increasing use of spatial awareness in reduced size electronics and IoT, is expected to witness increasing market demand.

Current microelectromechanical system (MEMS) fabrication technologies for inertial sensors are limited by the ability to produce sufficiently small sensors, which are required for numerous applications. Lack of measurement repeatability in varied environments is a limiting factor in current systems, and measurement drift over time prevents the extended use of current smallest devices, prohibiting use, for instance, in critical applications (e.g., military systems). The wide-spread size reduction trend, pushing MEMS into the NEMS scale, is also prominent in consumer electronics, where an increasing number of components in mobile phones and wearable electronics are being compacted to fit within limited space and power constraints. A similar trend has been seen in the medical field, where medical implants for diagnosis and patient monitoring are constantly being reduced in order to enable extremely high accuracy and to minimize invasiveness. Similarly, automotive systems, such as airbag control and rollover detection, require many smaller and lighter inertial sensors, and demand is only increasing as vehicles incorporate more smart technologies.

The growing pressure to reduce the size of electronics is driving innovation in large-scale production of more miniaturized components. The presented new inertial nanosensor technology provides a unique opportunity to develop reliable and durable inertial sensors that are in the nanoscale, increasing functionalities in portable electronic devices.

A novel structure for inertial sensors with a motion detection mechanism based on the piezoresistive effect that enables drastic size reduction of the sensing device to the nanoscale. The novel device incorporates inorganic nanotubes for increased sensitivity and reliability.

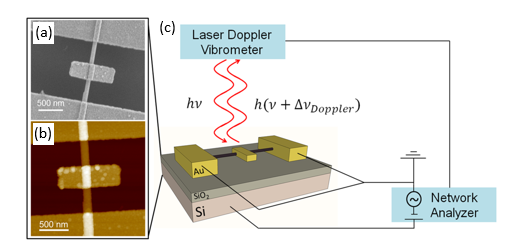

The structure of the inertial sensor consists of a suspended nanotube clamped between metallic pads at its ends, with a suspended pedal attached at the top (see Figure 1). The pedal is off-centered with respect to the nanotube, so each end of the pedal stands at a different distance from the nanotube. The structure was fabricated using electron-beam lithography, followed by wet-etching and critical point drying. In order to measure the oscillatory behavior of the torsional resonators, a DC bias voltage and a smaller AC drive voltage are applied between the substrate and the pedal. The alternating voltage between the substrate and the pedal combined with the offset of the center of the pedal with respect to the nanotube, creates an oscillatory net torque on the pedal, leading to periodic twisting the nanotube. The pedal vibration detection can be detected using an electric signal.

(a) Scanning electron microscope image and (b) atomic force microscope image of the nanotube-based inertial sensor. (c) The inertial sensor is actuated by applying voltage between the substrate and the offset pedal, which is attached to the nanotube.

Advantages

- Nanoscale (pedal dimensions of >300x800 nm)

- The output is an electrical signal

- Based on inorganic nanotubes with high durability, allowing extended time operation

- High accuracy and sensitivity (torsional resonance frequency of 20 ± 4 MHz).

Applications

- Nanosensors can be used for various applications including:

- IoT devices

- Navigation systems

- Wearable sensors (smart watches and fitness trackers)

- High-resolution camera stabilization

- 3D gaming

- Medical implants and devices.

Successful operation of the inertial nanosensor device was demonstrated (published in: Nano Lett. 2017, 17;1: 28-35). Yeda Research and Development, the technology transfer arm of the Weizmann Institute of Science, has filed a patent application and is working with Prof. Joselevich’s lab to develop a proof-of-concept prototype with an electrical output rather than the optical signal described in the publication.

Market demand will be driven by incorporation of inertial sensors into a wide range of mass-produced consumer electronics, medical sensors and vehicles. As wearable electronics become widespread, the demand for inertial sensor technology is expected to be the most prominent in consumer devices markets. The global sensor market is projected to reach $241 billion by 2022, with an 11.3% CAGR, with the NEMS sector estimated to have a growth rate of 14.3%.

As NEMS technology develops in industry, it is expected to integrate with existing MEMS, to reduce production costs and increase product accuracy. The inertial sensors MEMS market, including oscillators, gyroscopes, accelerometers and inertial combos, is currently estimated at $4.4 billion and is expected to grow ever faster than previously, due to widespread adoption of sensors to enable wireless and internet connectivity, with a CAGR between 15-20%. NEMS will also increase the value of several IoT hardware markets. The IoT market as a whole is projected to reach $46 billion by 2024 with a CAGR of 17%.

Dr. Vered Pardo Yissar